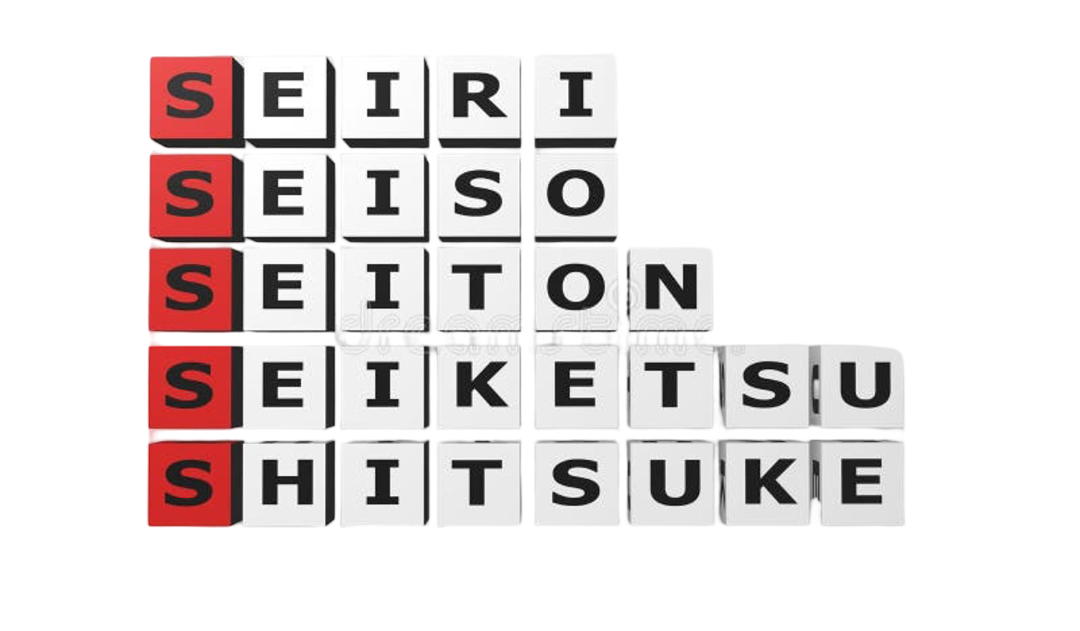

5S: The Japanese discipline applied to precision repair

At Comter México, quality is not an abstract concept or an isolated department. It is the result of a daily discipline shared by our entire team. That is why the 5S methodology, originally from Japan, is not just another item on our list—it is the foundation on which we build the reliability of every repair we perform.

When a critical electronic control reaches our hands, we don't just diagnose a fault. Our work environment, governed by 5S principles, ensures the order, cleanliness and standardization needed to handle sensitive components with the precision demanded by companies like Molex, Flex and Sanmina. We don't just repair; we do it in an environment that ensures traceability and quality from the first moment.

The 5S explained with our experience

Separate the necessary from the unnecessary. On our workstations, only what will be used in the current repair is present. Components, tools and documents from the previous repair are removed immediately. This eliminates confusion and prevents mixing or loss of small parts.

"A place for everything and everything in its place." Our component warehouse is organized with codes and cross-references. Precision tools (tweezers, soldering irons, magnifiers) have their designated spot and are returned after use. This minimizes search time and protects equipment.

Inspect while cleaning. In a board repair environment, cleanliness is critical. We not only keep areas spotless—we visually inspect the condition of our benches, magnifiers and soldering stations while cleaning. A dust- and metal-residue-free environment means quality in micro-soldering.

Create rules to maintain the first three pillars. We have developed visual standard operating procedures (SOPs) for work area preparation, board handling and post-repair cleaning. Every technician follows the same steps, ensuring consistency and quality regardless of job complexity.

Turn the first 4S into an ingrained habit. Our team is trained and committed to continuous improvement. It's not about following a checklist—it's about having the awareness and professional pride to maintain the highest standard in every repair, every shift, every day. This is the foundation of our reliability.

Seiri (整理) in practice

Separate the necessary from the unnecessary: at each station only what is used in the current repair is present. This way we avoid confusion and part loss, and maintain the standard our clients demand.

The result of discipline

When 5S is real, results are visible.

Consistent quality in every repair

Standardization eliminates variability. We know the process is followed the same way for a simple PLC as for a complex servo drive.

Traceability and safety

Order allows us to identify component lots, repair dates and responsible technician. A clean environment is also a safe environment for our team.

Faster response time

With everything in order and classified, we spend more time diagnosing and repairing, and less time searching for tools or components. Your downtime is reduced.

Trust from demanding clients

Being able to show a work area that meets the highest organization standards is the calling card that companies like those who already trust us expect. We don't just say it—we demonstrate it.